Welcome to pdmotion

I try to transfer all the images of works what I had done a long ago. I may be able to make here more vitalize.

Thanks!

Thursday, December 20, 2007

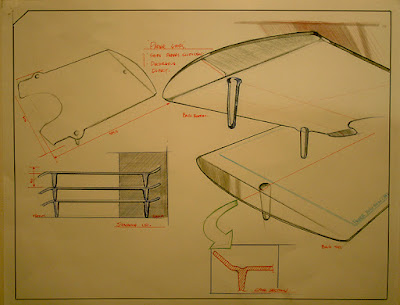

Process - II : Detailed sketch.

Process - I : Sketch for desk accessaries

The first step sketches that show various styles and ideas.

colour pencils and markers are used to present

colour pencils and markers are used to present

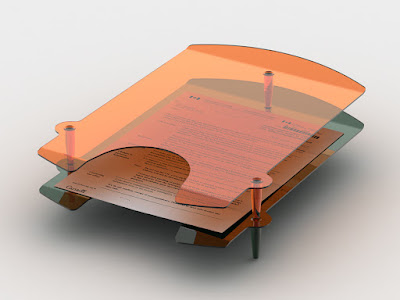

building up desk model.

Monday, December 10, 2007

Form and Colour - Carving an Object

Thermoforming.

holes to hold pegs

*pegs are in the holes

*cross section to show variation of wall thickness

* showing variation of wall thickness

* stairs for pegs

* Overall design with pegs and dice

* filling up the gap with woodfiller

* dry up the mold

Creating 3D form through the “Thermoforming” with using sheet plastic material, this project focuses on designing forms which are quite sophisticated. The factors such as “Draw ratio”, “Wall thickness” and “Draft” should be understandable for the project. As well all the factors are delivered by the manipulation of specific techniques for the manufacture of the mold.Particularly, a game borad which is called as “TROUBLE” is applied for this project.

Thursday, August 9, 2007

the work

Tuesday, August 7, 2007

the modeling

the completed model without mapping.

the concept.

Abstract

The objective of a wheelbarrow is to be able to move heavy loads of gardening or constructing materials; for instance, bags of soil for personal gardening purposes. Thus, a wheelbarrow provides efficiency and convenience in such a working. Durable and rugged material guarantees long term reliability and seamless structure of the tray ensures safety to users. However, the product may require complements in regards to versatility to easily maneuver and use in various environments and circumstances.

Background

Currently, the overall structure of a wheelbarrow is specifically divided into three parts: (1) a seamless structure of the tray, which is used to store large loads, made of durable plastic or steel; (2) frames hold the tray, connect and keep the wheel(s) intact, and made of steel or wood extending to the handles; and (3) wheel(s) which allow users to easily carry and work at an unrestricted distance.

In a specific case of a certain wheelbarrow, the product tended to restrict mobility. It was not suited to run on iced or rough surfaces, therefore, exhausting the user at a faster rate. In another case, users experienced difficulty when having to carry loads upward on sloped surface. In addition, the wheelbarrow created difficulty in dumping materials on sloped surfaces because in order to dump out the load, the user was required to highly lift or stand up the wheelbarrow. Obviously, this scenario creates potential risks to the user while the user dumped out the load from the tray. Thus, it needs to be modified to be able to move upward and dump materials on sloped surfaces. As a result, from an ergonomical and functional perspective, a wheelbarrow ought to be designed to have more than one wheel and incorporate implementations for easy dumping. Also, it may require complements to move the wheelbarrow on the sloped surfaces.

Development process

Firstly, referring specifically the frame, the design profile was inspired by an impala that has a very dynamic profile. In order to eliminate the difficulties of current wheelbarrows: (1) it ought to be designed to have two wheels and an additional pair of handles; and (2) two wheels ensuring a wheelbarrow more reliability when in use and extra set of handles will allow two users to users to operate when necessary.

Secondly, a door designed at the front of the tray will open automatically while the user lifts up the wheelbarrow to dump out the materials. Therefore, the door will reduce potential risks to users having to lift the wheelbarrow. Thirdly, a removable safety bar was incorporated between the front handles providing convenience and stability while users carry up the wheelbarrow on a sloped surface. Furthermore, each part will be sold and stored separately so that users can easily purchase and assemble the wheelbarrow conveniently. The targeted market depends on the capacity and size of the wheelbarrow, the newly designed wheelbarrow may be used for various purpose such as personal gardening and up to a mid-size construction area.

The objective of a wheelbarrow is to be able to move heavy loads of gardening or constructing materials; for instance, bags of soil for personal gardening purposes. Thus, a wheelbarrow provides efficiency and convenience in such a working. Durable and rugged material guarantees long term reliability and seamless structure of the tray ensures safety to users. However, the product may require complements in regards to versatility to easily maneuver and use in various environments and circumstances.

Background

Currently, the overall structure of a wheelbarrow is specifically divided into three parts: (1) a seamless structure of the tray, which is used to store large loads, made of durable plastic or steel; (2) frames hold the tray, connect and keep the wheel(s) intact, and made of steel or wood extending to the handles; and (3) wheel(s) which allow users to easily carry and work at an unrestricted distance.

In a specific case of a certain wheelbarrow, the product tended to restrict mobility. It was not suited to run on iced or rough surfaces, therefore, exhausting the user at a faster rate. In another case, users experienced difficulty when having to carry loads upward on sloped surface. In addition, the wheelbarrow created difficulty in dumping materials on sloped surfaces because in order to dump out the load, the user was required to highly lift or stand up the wheelbarrow. Obviously, this scenario creates potential risks to the user while the user dumped out the load from the tray. Thus, it needs to be modified to be able to move upward and dump materials on sloped surfaces. As a result, from an ergonomical and functional perspective, a wheelbarrow ought to be designed to have more than one wheel and incorporate implementations for easy dumping. Also, it may require complements to move the wheelbarrow on the sloped surfaces.

Development process

Firstly, referring specifically the frame, the design profile was inspired by an impala that has a very dynamic profile. In order to eliminate the difficulties of current wheelbarrows: (1) it ought to be designed to have two wheels and an additional pair of handles; and (2) two wheels ensuring a wheelbarrow more reliability when in use and extra set of handles will allow two users to users to operate when necessary.

Secondly, a door designed at the front of the tray will open automatically while the user lifts up the wheelbarrow to dump out the materials. Therefore, the door will reduce potential risks to users having to lift the wheelbarrow. Thirdly, a removable safety bar was incorporated between the front handles providing convenience and stability while users carry up the wheelbarrow on a sloped surface. Furthermore, each part will be sold and stored separately so that users can easily purchase and assemble the wheelbarrow conveniently. The targeted market depends on the capacity and size of the wheelbarrow, the newly designed wheelbarrow may be used for various purpose such as personal gardening and up to a mid-size construction area.

Subscribe to:

Comments (Atom)